Initiatives for Growth

We will continue to grow for a vibrant NHK Spring future.

2026 Medium-Term Management Plan

The entire group is committed to working for achievement of our Medium-Term Management Plan, which will end in FY2026.

Growth Strategy in Each Business Segment Geared to Achievement of the 2026 Medium-Term Management Plan

To achieve the 2026 Medium-Term Management Plan, we have identified themes for measures in five business segments based on our basic policy.

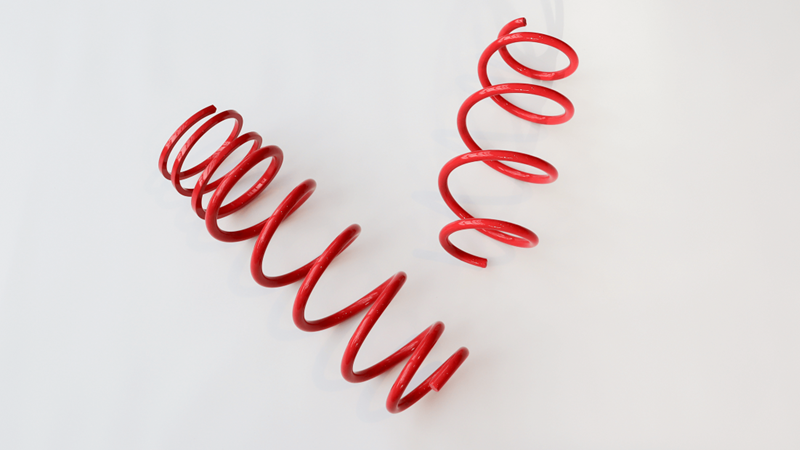

Automotive Suspension Springs Business

・ Efforts towards achieving profitability at two North American bases

・ New technology and product development and market launch to improve competitiveness

・ Improving productivity through promoting manufacturing reforms

・ Strengthening the global production technology support system

Seating Business

・ Focusing on developing seats that respond to electrification, autonomous driving, and environmental issues

・ Eliminating heavy labor through the use of robots and automation

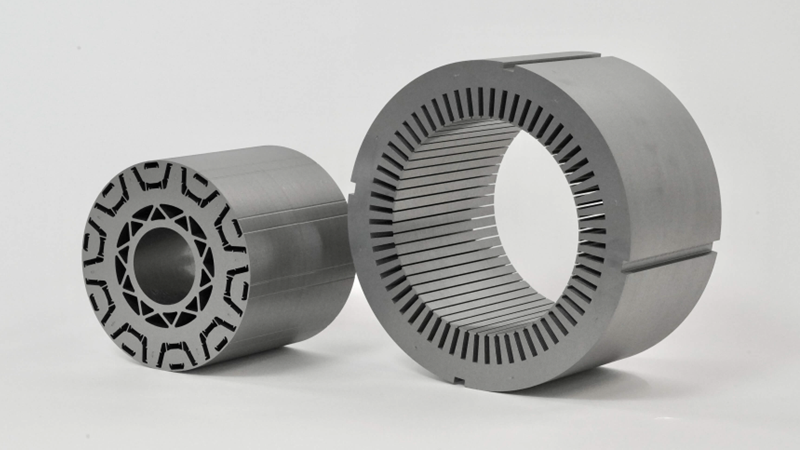

Precision Springs and Components Business

・ Expanding the motor core business

・ Efforts towards electrification

・ Strengthening the profitability of existing businesses

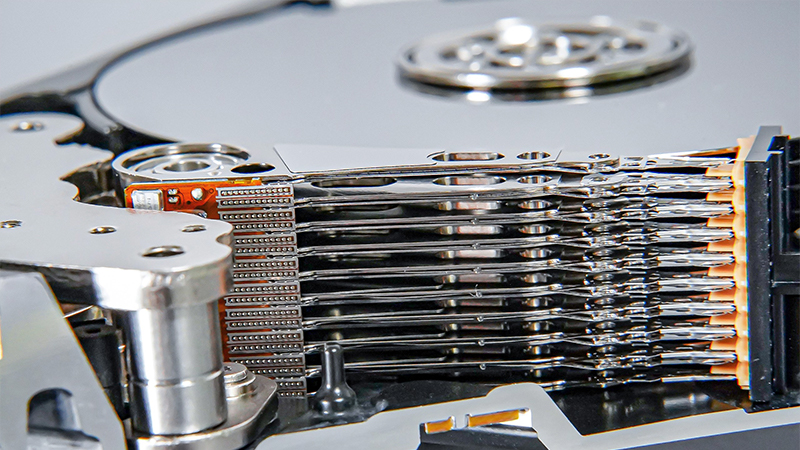

Disk Drive Suspensions

Business

・ Promoting smart factory

・ Increasing market recognition and establishing a business foundation through sales expansion

・ Exploring new products leveraging Disk Drive Suspension core technology

Industrial Machinery and Equipment, and Other Business

・ Strengthening the system in line with the business expansion of semiconductor process components

・ Establishing a mass production system for integrated metal substrates

・ Ending the chemical products business and transferring/consolidating equipment among Japanese bases

FEATURED PRODUCTS OF NHK SPRING

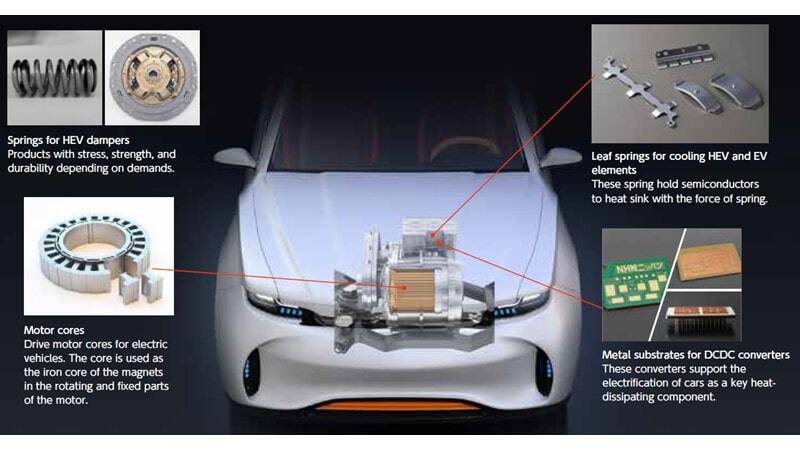

① Response to CASE ~Deployment of Electric Vehicle Related Components~

The automotive industry is said to be undergoing a "once-in-a-century transformation" in recent years.

The number of electric vehicles is increasing every year and is expected to grow even more.

We are leveraging NHK Spring's technology to advance development and production catering to the 'E' (electrification) of "CASE".

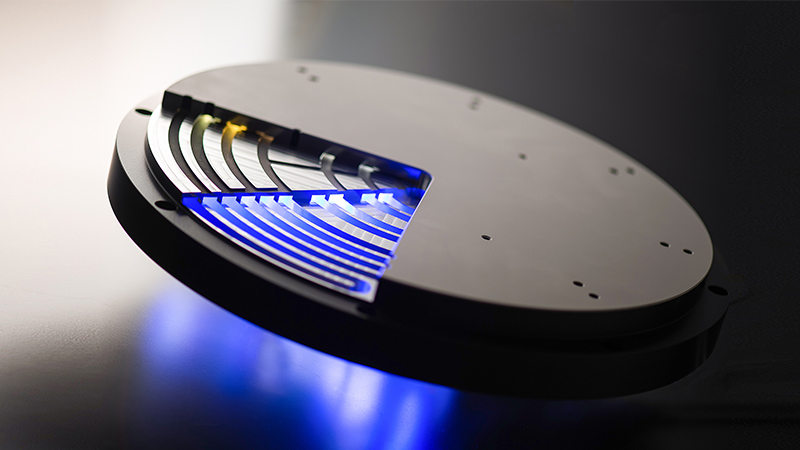

② Semiconductor process components ~ NHK Spring's products other than springs~

Semiconductor process components, as the name implies, are used in semiconductor manufacturing processes.

We develop and manufacture these components using the high-level bonding technology that NHK Spring has cultivated over many years.

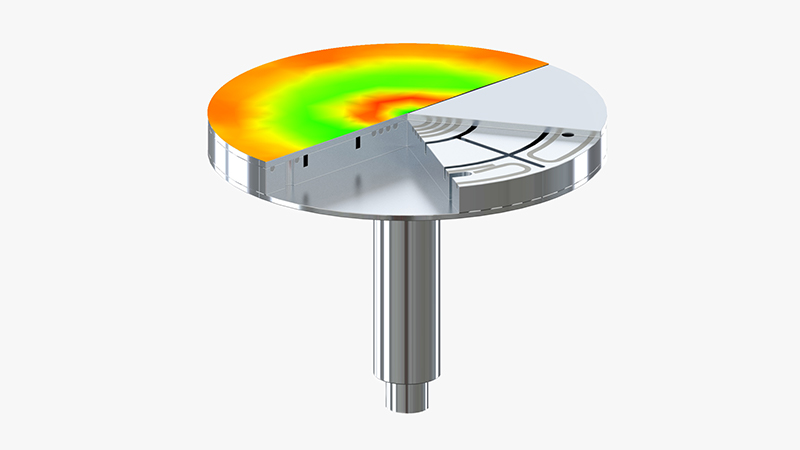

Stage heaters for film-forming equipment multi-zone control

These products are used in film-forming, which is a key process in the manufacture of semiconductors.

They enable not only uniform temperature distribution but also active temperature distribution control.

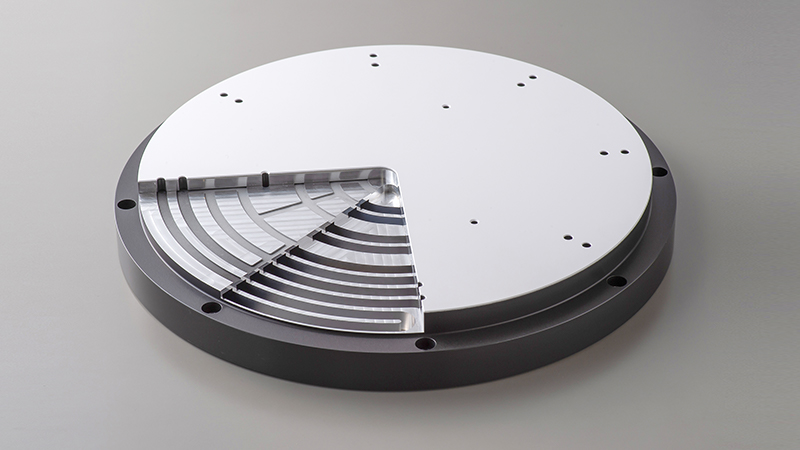

Cooling plates with thermal spraying for etching equipment

Similarly, these products are used in etching, which is another key process in the manufacture of semiconductors.

These are important stage components on which silicon wafers are loaded during the manufacturing process.

Initially, we only conducted production at the Isehara Plant in Kanagawa Prefecture, however, in order to respond to the strong market, we actively invested in sales expansion by establishing a new Miyada Plant in Nagano Prefecture in 2019 and expanding the plant in 2024.

<Semiconductor Process Components: Market Trends and Sales Trends>

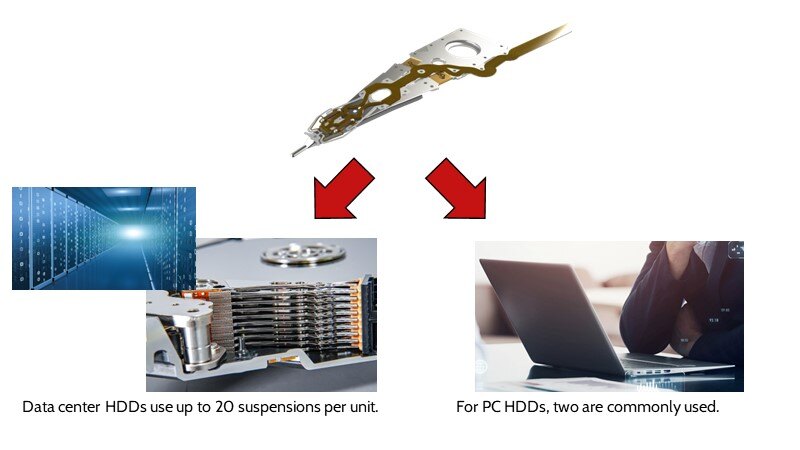

③ HDD suspensions ~ NHK Spring products in non-automotive fields ~

HDD (hard disk drive) suspensions are special spring products that support the micro components that read and write data on disks.

Currently, more than the number of HDDs in PCs, there are far more HDDs in the data centers of companies that operate social networking and video-sharing site services, etc., where ultra-large capacity HDDs are lined up by the hundreds of thousands.

In a data center, up to 20 HDD suspensions are used per unit.

As a result, demand for NHK Spring's HDD suspensions is increasing, and we see this as an opportunity to develop HDD suspensions with even higher capacity.

NHK Spring's Environmental Challenges for a Sustainable Society

NHK Spring has declared the following Environmental Challenges

To realize a sustainable society, we are promoting environmental initiatives throughout the NHK Spring Group.

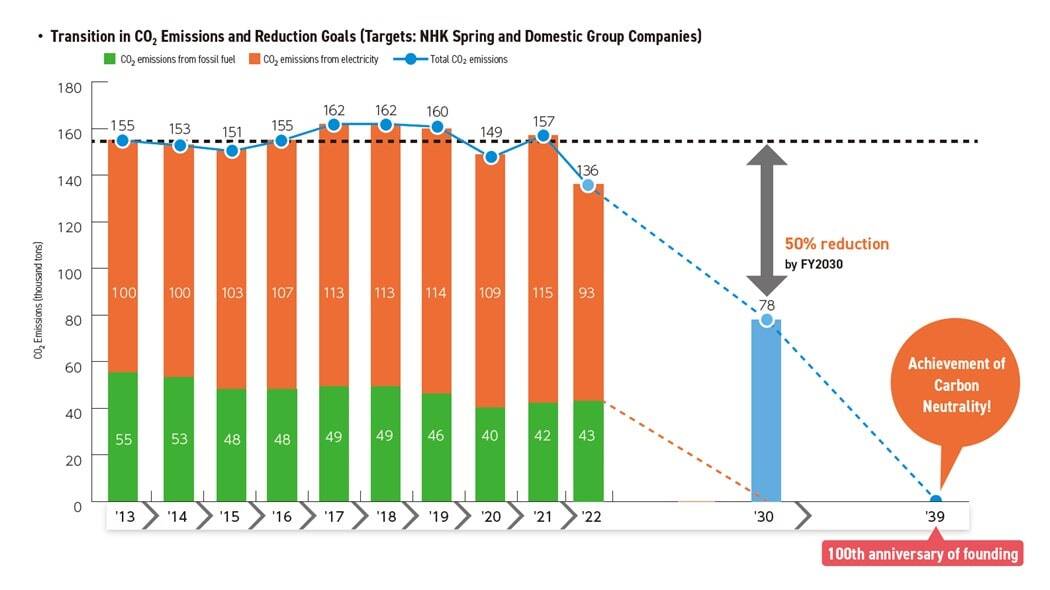

① Achievement of carbon neutrality by 2039

Carbon neutrality is an initiative to achieve a balance (neutrality) between the amount of CO₂ emitted by human activities and the amount of CO₂ absorbed by forests, oceans, etc.

We have set an interim target of a 50% reduction from the fiscal 2013 level by 2030, and aim to achieve carbon neutrality by 2039, which will mark the 100th anniversary of NHK Spring's founding.

② Aim for zero industrial wastes

Industrial waste refers to specific waste generated from business activities and other sources, and is considered to have a higher environmental impact than household and other general wastes.

NHK Spring has been working to reduce industrial waste since 1993 and has achieved zero emissions at its domestic plants.

By 2030, we aim to achieve "zero" industrial waste over the entire NHK Spring Group, including overseas plants.