Our Strength

NHK Spring's strengths can be found in our world-class "manufacturing capabilities" and "business base" nurtured over many years since our establishment.

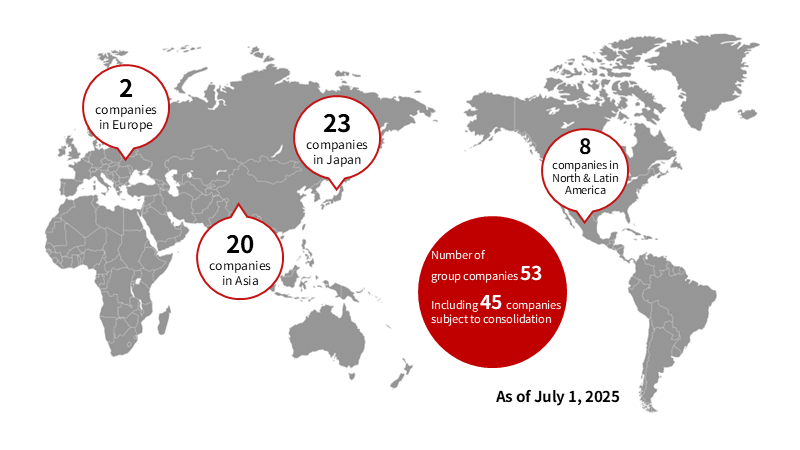

Global Business Development

NHK Spring Group operates not only domestically but also globally. Based on our desire to be "always close to our customers", we have established many bases in the United States, Asia, and Europe and are developing as a global supplier that can "optimize procurement". Another strength lies in the relations of trust we have built up with all automobile manufacturers in Japan.

Manufacturing Capabilities that Support Society

NHK Spring strives for optimal manufacturing by combining R&D and production technologies.

Research and Development

We develop unique products based on our five core technologies.

Here are some of the products that leverage our strengths.

Metal Processing Technology

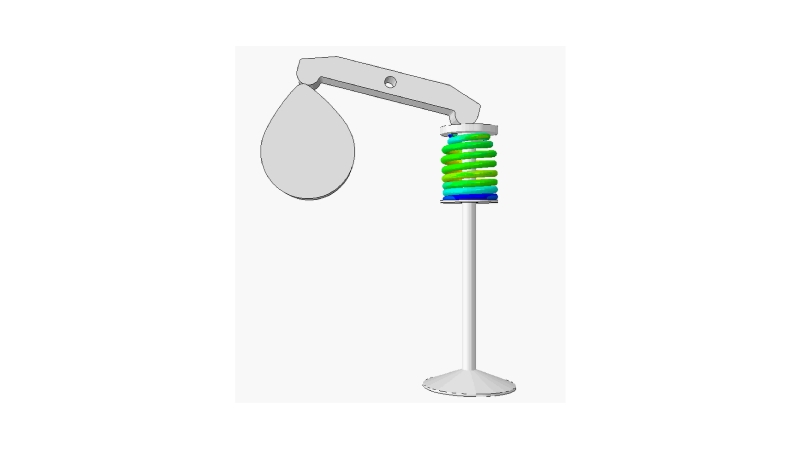

Simulation Technology

Bonding Technology

Heat Treatment Technology

Materials Development Technology

Example 1: Automotive seats

Advanced metal processing of seat frames

High-tensile steel, the material used for seat frames, is thin and has a rigidity that makes it difficult to deform.

Processing it requires sophisticated technology.

The only urethane formulation by a seat manufacturer

NHK Spring is the only seat manufacturer capable of developing and formulating its own urethane materials.

We can provide products that meet customers' requirements for comfort, durability, etc.

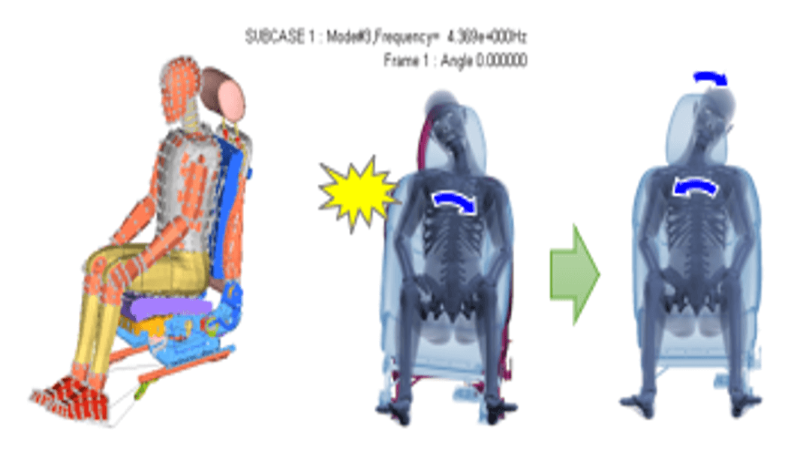

Improvement of ride comfort utilizing simulation

We utilize NHK Spring's analysis technology to quantify the subjective human sensation of "ride comfort" and improve performance.

This technology also allows us to conduct development more efficiently.

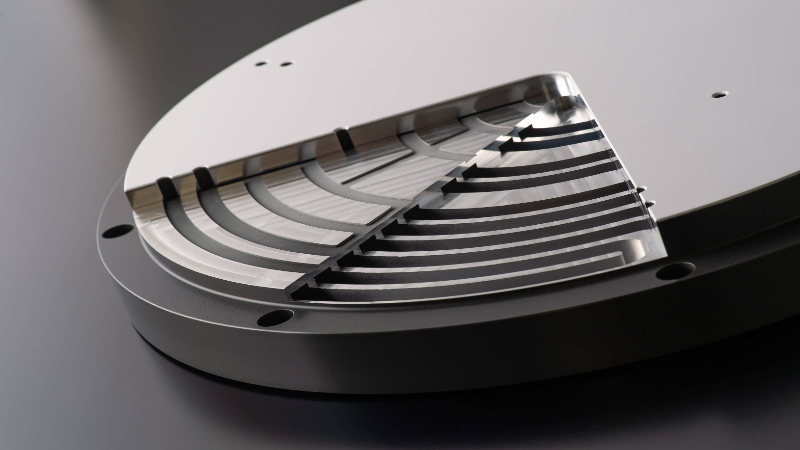

Example 2: Semiconductor process components

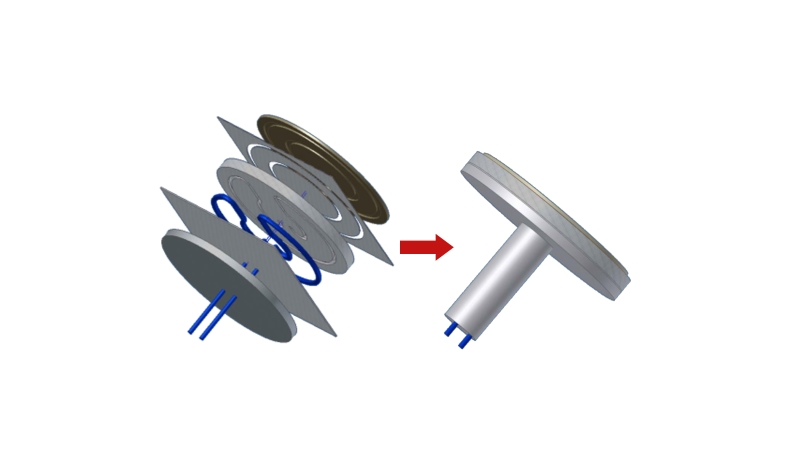

Metal bonding using NHK Spring's original technology

These parts, which are used in the semiconductor manufacturing process, entail joining of different types of metals.

The joining method called thermal spraying is commonly used, but this method has a disadvantage in that it is prone to distortions.

In contrast, NHK Spring's proprietary joining method called "brazing material" can join even complex shapes and achieve more stable quality without distortions.

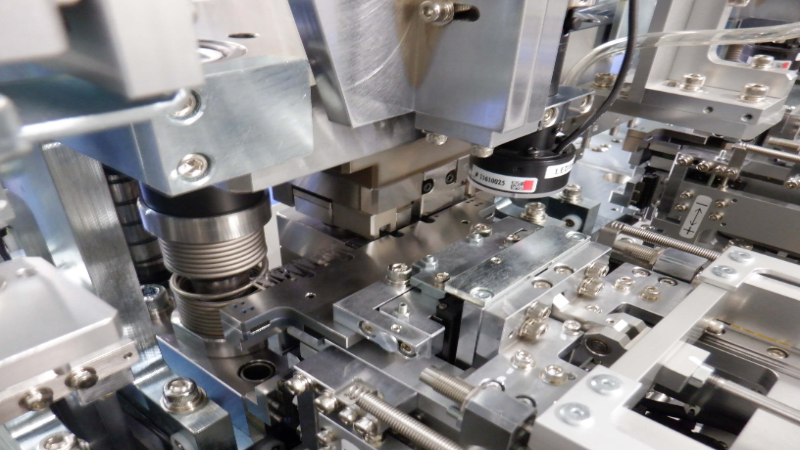

Production Technology

We are working to improve productivity by adopting automation to save labor in production processes.

Work automation by robots

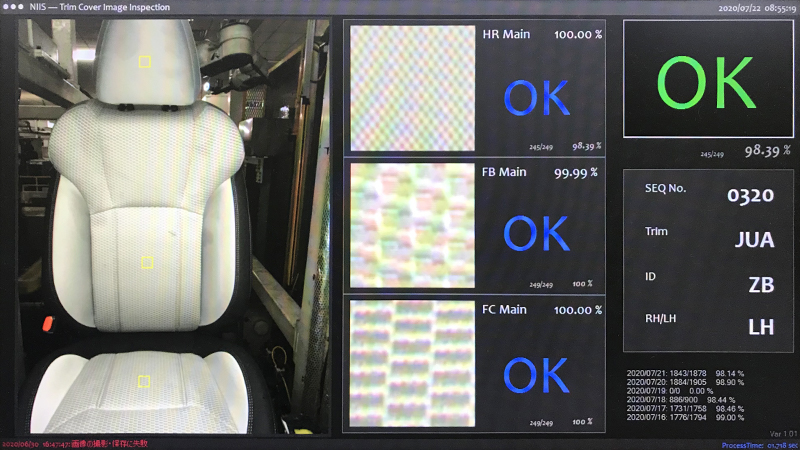

Automated and manpower-saving inspections of seats for wrinkles and other defects through utilization of AI

Quality Assurance

We are committed to manufacturing reliable products through implementing quality-first manufacturing. In recognition of our efforts, we receive awards from several customers every year.

<Development of a culture of quality and improvement of group governance>

We have continued to implement problem-solving activities using QC methods (QC circle activities) since 1965. We also implement such activities overseas.

Quality compliance training in cooperation with the legal department

<Quality control at every stage of manufacturing>

-

Development and Design

Computer simulation of springs, durability testing of car seats, etc.

-

Manufacturing

Coiling machines developed in-house and automated manufacturing lines utilizing robots, etc.

-

Inspection and Measurement

Manufacturing inspections by highly qualified inspectors and in-house automatic inspection machines, etc.

Stable Financial Base

We maintain a credit rating of "A (Stable)" (rated by Rating and Investment Information, Inc. (R&I)) and strive to establish a stable financial base and strengthen our risk structure. This enables us to procure funds at low interest rates.