Metal Working Technology

NHK Spring supplies key parts to a variety of industries, including the automotive sector, the information and communications sector including the semiconductor industry, and industrial and lifestyle sectors. Our corporate activities are built upon the foundation of metal working technology.

POINT1

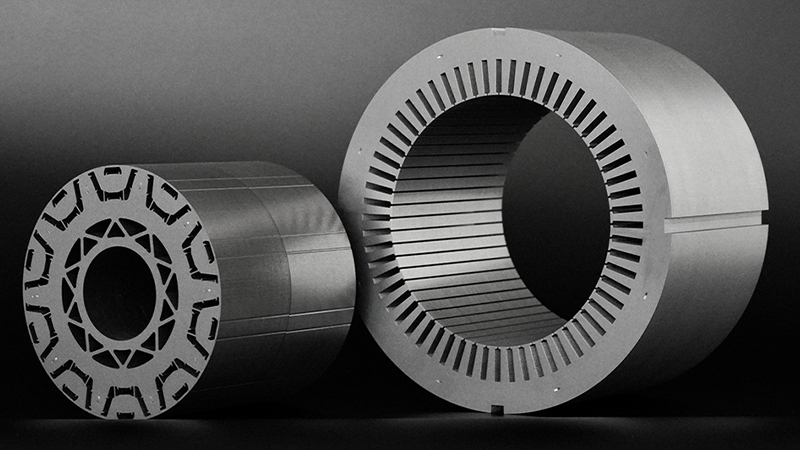

Motor Cores Designed, Developed and Produced from Dies In-house

We have advanced and highly precise press working capabilities supported by die machining technologies that enable us to manufacture our own dies and mass produce products of the quality required by our customers. Motor cores, which are key components for electric vehicles, are a typical example. Motor cores are the iron cores that generate the magnetic field in the motors used to drive electric vehicles, and their production requires a high degree of press working accuracy. We have three production bases around the world (Japan, China, and Mexico), and each location is capable of supplying products of the same level.

High-precision and high-speed press for making motor cores

In-house implementation of die design, manufacture and maintenance

.jpg)

POINT2

Processing Technologies for Springs

Since materials for springs are hard and cannot afford to have even the smallest flaw that could cause breakage, advanced processing technology is needed. In addition to press working and wire bending to form springs of various sizes for automobiles, we are also pursuing shot peening to improve fatigue strength and microfabrication technologies to manufacture extremely small springs for the increasingly sophisticated telecommunications field.