CO₂ Reduction Activities in NHK Spring Group

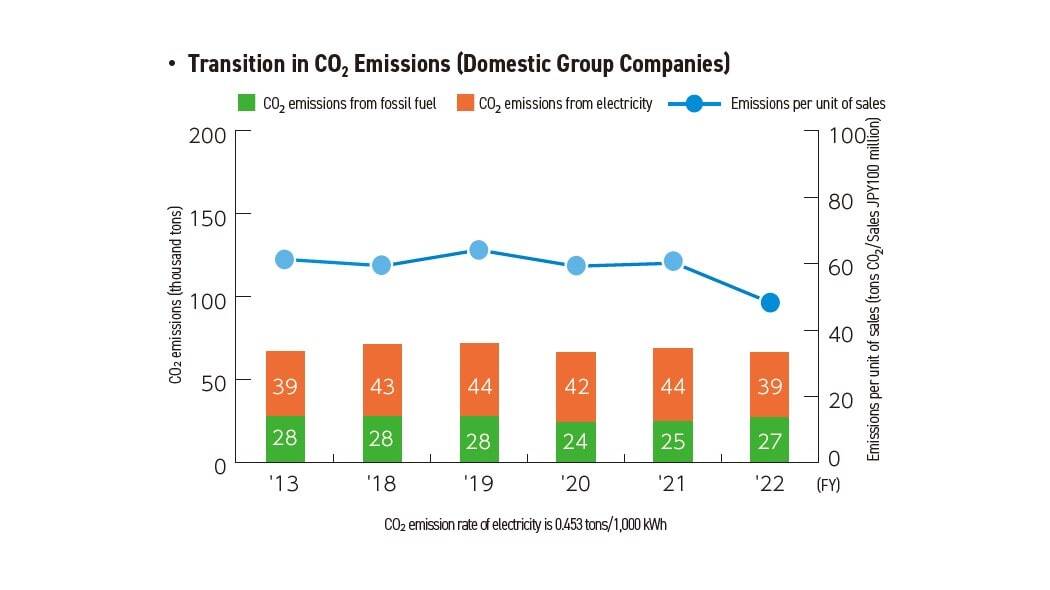

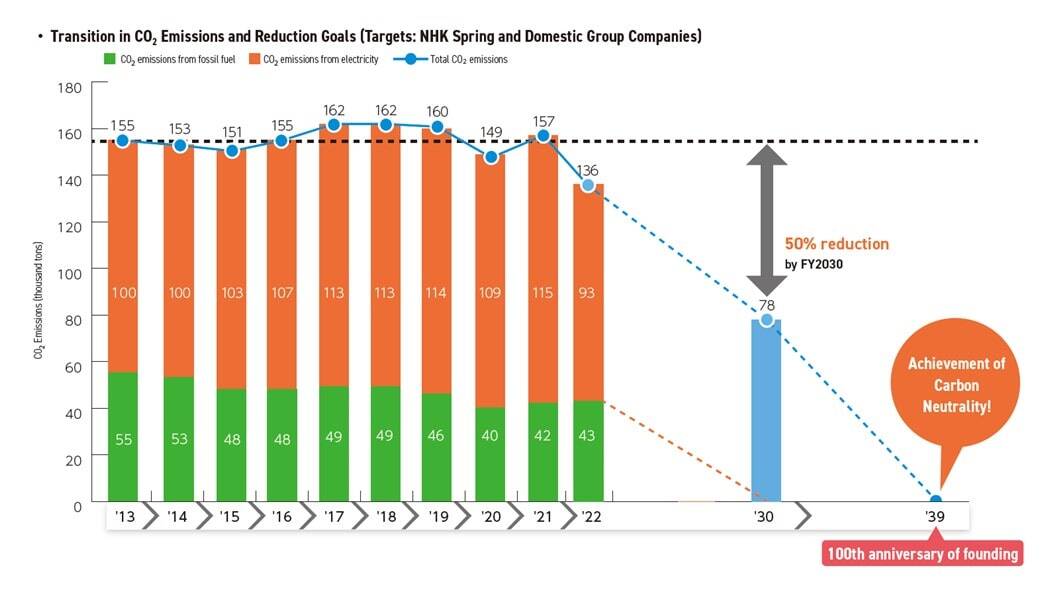

Having set reduction targets for CO₂ emissions calculated according to the amount of energy consumption, NHK Spring Group is committed to implementing global environmental conservation activities. Up to FY2020, we managed our CO₂ emissions per unit of sales, but since FY2021 we have switched to managing based on total emissions in order to achieve carbon neutrality.

We will also continue to compare with the past activities based on per unit of sales to verify the performance.

CO₂ Reduction Activities in FY2022

In FY2022, CO₂ emissions decreased in NHK Spring and domestic Group companies. Sales displayed a trend of increase in the same way as the previous year, however, CO₂ emissions decreased due to execution of CO₂ emissions reduction plans based on the Environmental Challenges that were declared in September 2021. CO₂ emissions also decreased on the per-unit-of-sales basis. NHK Spring and domestic Group companies implemented measures such as (1) updating compressors to optimize control, (2) replacing aging air conditioners, (3) electrifying boilers that use fossil fuels, and (4) reducing and discontinuing use of equipment. In addition, we introduced solar power generation facilities and purchased renewable energies.

At sales offices and other business sites, we ensure that power is turned off in unoccupied office rooms and thin out fluorescent lights.

We have also reduced the amount of electricity used in offices through efforts to promote on-time work and telework as part of our work style reforms.

NHK Spring Group is first advancing the reduction of CO₂ emissions in domestic business sites. Overseas sites are conducting activities corresponding to the activities conducted in Japan.

.jpg)

Sharing of CO₂ Reduction Technologies (CO₂ Reduction Activity Awards)

NHK Spring Group is taking various measures to promote CO₂ reduction. In order to share these technologies throughout the Group, we hold annual awards for CO₂ reduction activities. Business sites compete with each other on countermeasure technologies, and effective countermeasure technologies are shared throughout the group.

FY2022 Awards

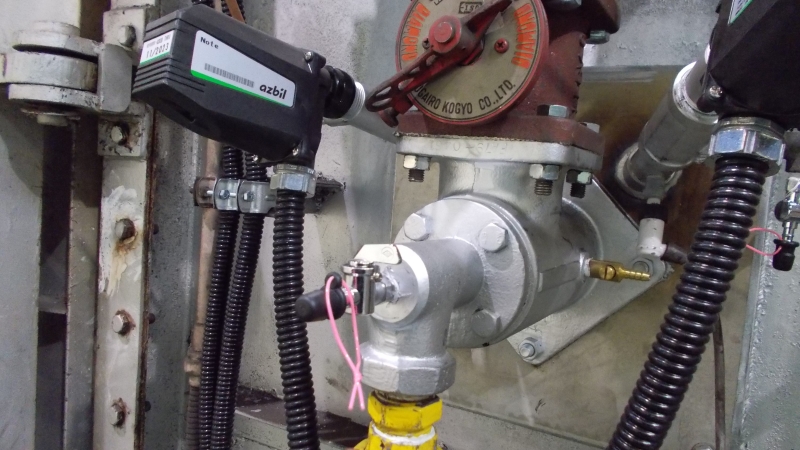

President's Award: HORIKIRI, INC., "LPG fuel conversion based on LNG (city gas)"

The company plans to conduct heat treatment, which is currently conducted using kerosene and LPG, entirely with LNG (city gas). Because LNG has a lower CO₂ emission rate vis-a-vis unit heat generation than LPG and kerosene, it contributes to achieving carbon neutrality.

The company has succeeded in reducing CO₂ emissions (78 tons/year) by converting fuel in a heating furnace, tempering furnace and two drying furnaces.

To protect the global environment, the entire NHK Spring Group will continue to actively exchange opinions and make continuous, all-out efforts to reduce CO₂ emissions.

CO₂ reduction of 4,183 tons over the past five years

(Total for FY2018 - 2022)

| FY | Award | Business site | Contents |

| FY2018 | President's Award | DDS Komagane Plant | Air consumption reduction based on improvement of production facilities |

| Chairperson’s Award | Komagane Plant (Industrial Machinery and Equipment) | CO₂ reduction by reviewing clean room operation methods | |

| FY2019 | Chairperson’s Award | Yokohama Plant (Seating) | CO₂ reduction through adoption of package air conditioning |

| Chairperson’s Award | Isehara Plant No.1 | CO₂ reduction by reviewing equipment cooling methods | |

| Chairperson’s Award | DDS Komagane Plant | Reduction of energy consumption during shutdown periods | |

| FY2020 | President's Award | Atsugi Plant | Saving electricity by optimizing hydraulic pump discharge pressure |

| Chairperson’s Award | Yokohama Plant (Suspension Springs) | Power saving by restructuring control of the number of compressors | |

| FY2021 | Chairperson’s Award | Gunma Plant | Reduction of steam consumption through piping optimization |

| Chairperson’s Award | Tokuhatsu Co., Ltd. (Itami Plant) | Energy saving by adjusting exhaust fan speeds | |

| FY2022 | President's Award | HORIKIRI, INC. Head Office plant | LPG fuel conversion by LNG (city gas) |

| Chairperson’s Award | Yokohama Plant (Seating) | Reduction of power consumption based on insulation measures using urethane foam dies | |

| Chairperson’s Award | Topura Co., Ltd. Tokai Plant | Shortening of distance between products undergoing heat treatment |