Quality Assurance Management

In addition to supplying products of appropriate quality and constantly striving to raise levels of delivery and cost, we aim to improve "customer satisfaction".

Quality Assurance Initiatives

Through fostering a culture of quality from the customer's perspective, we aim to provide customers with products of appropriate quality and to continue to maintain a high level of "customer satisfaction" on a global basis with respect to meeting our established delivery deadlines and cost targets.

Quality Assurance

Aiming to further improve customer satisfaction, we promote "quality-first" manufacturing from development and design to production.

Quality-first manufacturing is NHK Spring's most important mission. In order to establish a quality assurance system that works around the world, the entire NHK Spring group is striving to obtain ISO9000 series and IATF16949 certifications. We strive to improve customer satisfaction through quality improvement activities at every stage of manufacturing.

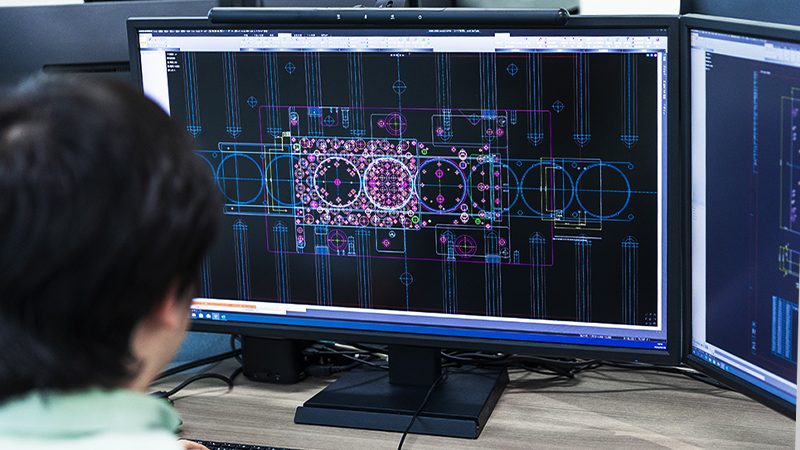

In the development and design stages, we utilize and fully evaluate various preventive methods to produce high quality products. In the production preparation stage, we strive for a smooth and trouble-free start-up using the latest equipment and optimal production systems.

Moreover, we actively introduce new technologies and constantly pursue quality improvement. In addition, we conduct thorough quality evaluation and quality improvement from all angles, including FMEA, design review, quality confirmation at each process, and reliability testing, to ensure consistent quality assurance.

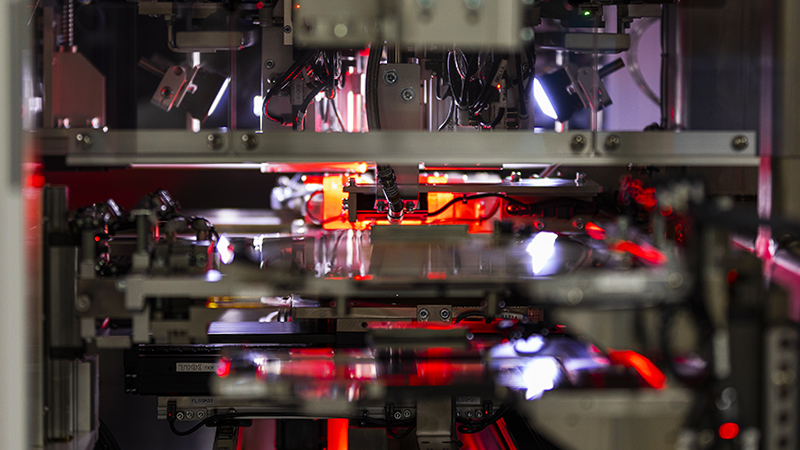

Spring coiling

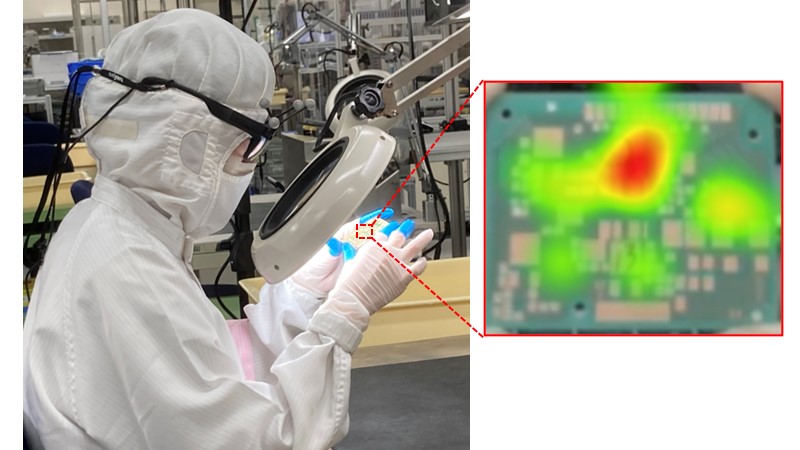

Camera inspection of HDD suspensions

Die design

QUALITY POLICY

Quality Policy

FY2026 Mid-Term Quality Policy

To achieve global improvement in customer satisfaction by competitive quality based on human resource development and fostering a quality culture.

FY2024 Priority Measures

(1)Promote activities to ensure compliance and strengthen governance, and then reinforce weak points through checking milestones.

(2)Promote “quality DX activities” by utilizing information and automating processes to achieve competitive quality.

Awards received from customers

Some examples of awards received from customers

FY2022

Domestic

-

Nissan Motor Co., Ltd. Certificate of Appreciation for Outstanding Quality

-

Honda Motor Co., Ltd. Certificate of Appreciation for Excellence (Quality Division)

-

DAIHATSU MOTOR CO., LTD. Quality Excellence Award

-

AISIN CORPORATION Quality Excellence Award

-

JATCO Ltd Regional Quality Award

-

EXEDY Corporation Outstanding Quality Award

Overseas

-

Toyota Motor North America, Inc. Quality Achievement(SEAT)

-

Toyota Kirloskar Motor Ltd. Zero PPM & Quality Certification

-

Honda Cars India Ltd. BRONZE AWARD "NON-CURRENT"

-

JATCO (Guangzhou&Suzhou) Automatic Transmission Ltd. Quality Award

FY2023

Domestic

-

TOYOTA MOTOR CORPORATION TOYOTA GAZOO Racing Company Certificate of Appreciation for Technology and Quality

-

Nissan Motor Co., Ltd. Certificate of Appreciation for Outstanding Quality

-

NISSAN SHATAI CO., LTD. Certificate of Appreciation for Quality Contribution

-

Hino Motors,Ltd. Outstanding Quality Control Award

-

EXEDY Corporation Outstanding Quality Award

Overseas

-

Nissan North America, Inc. Quality Master Certificate

-

Isuzu Engine Manufacturing Co., (Thailand) Ltd. FY2023 QD Awards

-

Hino Motors Manufacturing (Thailand) Ltd. Best Quality Performance, Silver Award

-

JATCO (Guangzhou&Suzhou) Automatic Transmission Ltd. Quality Award

-

Jatco Mexico, S.A. de C.V. Quality Award

-

CHINA FCC FOSHAN CO., LTD. Outstanding Quality Award

Quality-First Manufacturing

Quality-first manufacturing is the most important mission of NHK Spring Group. We strive to improve customer satisfaction by managing quality at every stage of manufacturing.

100% inspection of accumulators using image processing technology

Accumulators are components that utilize high-pressure gas.

Because these parts are assembled by welding, it is not possible to check the interior following assembly.

Accordingly, on the latest automatic assembly lines, 100% inspections utilizing image processing technology are implemented immediately before assembly in order to guarantee reliable manufacturing and quality.

High-accuracy visual appearance inspections utilizing sightline measurement technology

Due to the recent diversification or increasingly compact-size products, inspectors are required to possess advanced skill for implementing numerous intricate visual inspections. To realize more accurate visual appearance inspections with less variation by large numbers of inspectors, we augment the skills of inspectors by leveraging sightline measurement technology.

Specifically, through visualizing the skill (sight trace, speed and stay time) of inspectors, we evaluate inspection procedures and conduct pertinent training. To certainly guarantee the high level of required quality, we incorporate new technologies and work to improve the skills of inspectors.

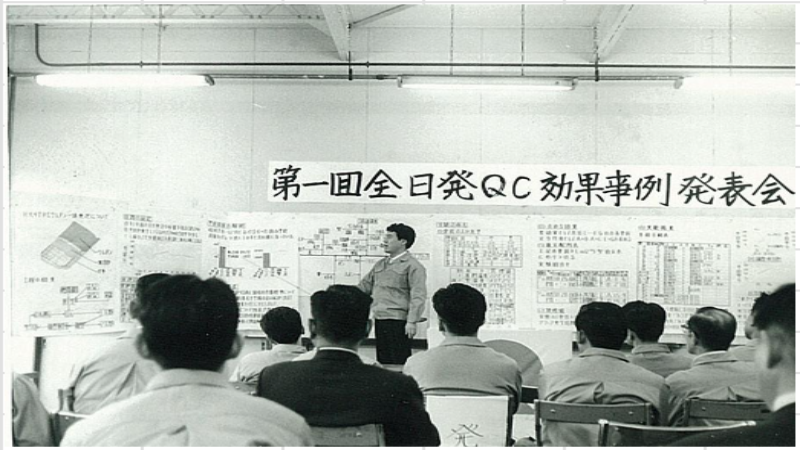

QC Circle Activities

Since 1965, we have been promoting QC circle activities in small groups using QC techniques as workplace improvement activities based on employee creativity and mutual development. We have continuously held QC circle conventions since the "First All-NHK QC Effectiveness Case Study Presentation Meeting" in 1966, and we changed the name to the All-NHK Spring QC Circle Convention in 1978.

Due to the spread of COVID-19, video review and online presentations were conducted in FY2020-FY2022. In FY2023, when the event was held in person for the first time in four years, a limit was placed on the number of participants.

QC circle activities are also actively conducted by Group companies. In Japan, regional competitions are held in two blocks (East and West) and a national competition is held for the top eight circles. Overseas, the NHK Spring Company-wide competition in Thailand and the national competition in China are very active, and the top QC circle in each country presents its results at the All-NHK Spring QC Circle Competition. Overseas QC circles are at such a high level that circles have won the top prize in the All-NHK Spring competition.

1966 First All-NHK QC Effectiveness Case Study Presentation Meeting

2023 President and CEO Mr. Kayamoto giving an address at the Convention

Fostering a Culture of Quality

Although quality control tends to be associated with "quality control technologies for objects", we believe that "it is people who create quality". Therefore, in addition to providing regular training on quality control technologies, we also focus on training aimed at "raising consciousness for fostering a culture of quality”. Within our education system that is tailored to different categories of new hires, mid-level employees and managers/supervisors, emphasis is placed not only on quality control technologies but also an attitude of "listening to the voices of customers and supplying satisfactory products" from each standpoint.

Moreover, from the viewpoint of widening the range of knowledge, we are devoting resources to not only group education but also on-demand contents that can be viewed by anybody in any place.

The customer decides whether quality is good or bad

-

Good quality

-

Something that is satisfactory to the customer

=The customer decides -

Not determined by specific performance or price alone

(Quality control education for new recruits in 2023)

Strengthening of Group Governance

The NHK Spring Group has established a quality assurance system at each production site and vigorously promotes quality control, audits, and improvement activities. In addition, our Quality Control Department regularly conducts independent audits at all domestic production sites. We implement a so-called "audit on auditing operations" to confirm that the systems and activities related to quality assurance are being properly implemented, and we conduct guidance to promptly rectify conditions if they are insufficient.

Moreover, the Quality Control Department and CSR Department, which manages compliance, continuously implement activities to foster a group-wide quality culture. By implementing a number of such initiatives over and over again, NHK Spring Group has formed a strong group governance system that leads to appropriate quality manufacturing at all production sites.